|

(Grand Island, Nebr.) — The Hornady® Ballistic Development Group (BDG), a specialty research and design group at Hornady Manufacturing, has developed a new line of match bullets for the ultimate in precision and long-range shooting.

By drawing on years of research and experience with existing products like the ELD-X® and ELD® Match bullet lines, state-of-the-art equipment including Doppler radar, high-speed camera systems, plus investment in advanced manufacturing machinery, processes and quality control measures, the BDG has developed the A-Tip™ line of match projectiles.

By drawing on years of research and experience with existing products like the ELD-X® and ELD® Match bullet lines, state-of-the-art equipment including Doppler radar, high-speed camera systems, plus investment in advanced manufacturing machinery, processes and quality control measures, the BDG has developed the A-Tip™ line of match projectiles.

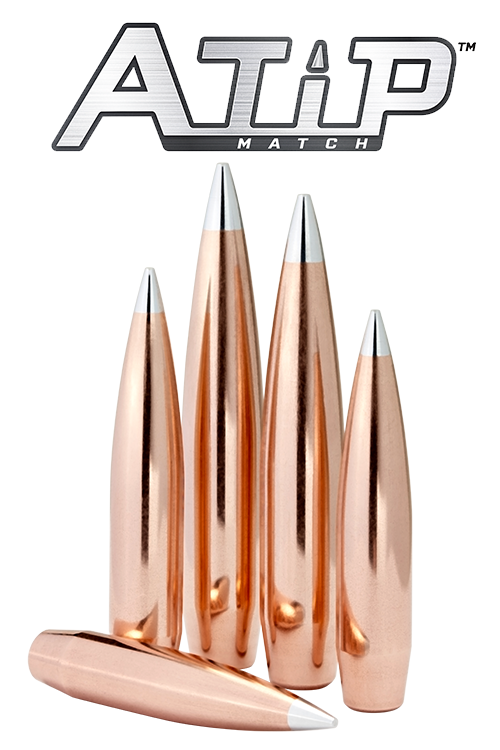

The most striking visual feature of the A-Tip™ bullet is its long, uniform, precision-machined aluminum tip.

“We wanted to incorporate aluminum tips in a full line of match bullets for years because we can make longer tips than we can with polymer materials,” said Joe Thielen, Assistant Director of Engineering. “This longer tip is a key component that helps move the center of gravity of the bullet rearward, thus enhancing in-flight stability and reducing dispersion. The problem has always been the cost to produce a tip like this, but we’ve developed a cost-effective process for manufacturing these aluminum tips while staying affordable for serious match shooters.”

The longer aluminum tips are machined to be caliber-specific, and when coupled with highly refined AMP® bullet jackets, aggressive profiles and optimized boattails, the result is enhanced drag efficiency (high BC) across the board. Each bullet design is carefully crafted for minimal drag variability for the utmost in shot-to-shot consistent downrange accuracy.

The materials, design and manufacturing techniques combine for the most consistent and accurate match bullets available.

“We designed the A-Tip™ projectiles with accuracy and precision first and foremost,” Thielen added. “Many low-drag bullets on the market today have very aggressive secant ogives, which look great on paper and yield high BCs, but usually these types of projectiles are very finicky when it comes to accuracy or performance in different chambers, standard twist rates, seating depths and barrels.”

In addition to developing projectiles that will shoot well in a variety of chambers, the BDG also designed the A-Tip™ bullets with the right balance between the center of gravity of the projectile versus center of pressure to minimize in-flight drag variability.

The A-Tip™ bullets are also packaged sequentially right off the bullet press without being batch handled or tumbled, ensuring that each bullet in the box is a clone of the bullet before it — and after it.

A-Tip™ bullets will be available in 100-count boxes, and retailers will also sell sleeves of five sequential 100-count boxes packaged together, as well as a case pack of two 500-count sleeves for a total of 1,000 sequentially packed bullets. Since the bullets will not be touched or tumbled, there will be some slight oil residue, so a bullet polishing bag will be included with each 100-count box for the hand loader to use in preparing bullets for loading.

This change in manufacturing and packaging is a welcome and unique challenge for a company built on large-scale manufacturing.

“We are frequently viewed as a very large bullet manufacturer, which in many ways we are, but the Ballistic Development Group runs like its own small ‘skunkworks’ division that allows us to offer the small-batch craftsmanship normally only offered by a boutique bullet maker,” said Jason Hornady, Vice President. “We’re shooters ourselves, and we also listen to what shooters want, and we are excited to be able to offer competitive and hard-core shooting enthusiasts projectiles that are undoubtedly the new standard bearer of precision and performance.”

Initial offerings of the A-Tip™ bullet include the following listings with Doppler radar measured G1 and G7 BCs:

·6mm 110 grain G1: .604 G7: .304

·6.5mm 135 grain G1: .637 G7: .321

·6.5mm 153 grain G1: .704 G7: .355

·30 caliber 230 grain G1: .823 G7: .414

·30 caliber 250 grain G1: .878 G7: .442

Use of a new A-Tip™ bullet seating stem is required for optimal bullet seating. Please visit hornady.com for full details.

A-Tip™ bullet BC values have been measured at Mach 2.25 and corrected back to International Civil Aviation Organization (ICAO) Standard Atmosphere (sea level, 59 degrees F, 29.92 inHg, 0% humidity).

Visit hornady.com/BC for BC values measured at Mach 2.0 and Mach 1.75 for calculating trajectories when shooting long distances.

Use of the Hornady® 4DOF® ballistic calculator with pre-populated A-Tip™ bullet drag curves will provide the most accurate calculations. Visithornady.com for full details.

Founded in 1949, Hornady® Manufacturing Company is a family owned business headquartered in Grand Island, Nebraska. Proudly manufacturing products that are made in the USA, Hornady® Manufacturing is a world leader in bullet, ammunition, reloading tool and accessory design and manufacture.

For further information regarding Hornady® products, visit the company web site at http://hornady.com.

# # #

For more information, contact:

Neal Emery

Marketing Communications Manager

Hornady® Manufacturing